“If you want to succeed in life, whatever this may mean to you, you have to be able to work with people. Life is teamwork. After all, we aren’t born alone, are we?” The beverage industry is highly competitive and requires effective enterprise risk management. In order to survive in it, one needs to innovate and collaborate. Innovation can mean bringing new products, and improved products, and it can mean rethinking and redesigning how things are done overall. At Malaki, we believe in all of these aspects. This blog is co-written by Rika, a friend of mine, who came to me with the idea to implement a bottle reuse system in India.

Considering the size of the beverage industry in India, incorporating risk management and making it more sustainable can contribute to creating a cleaner and more sustainable India. Sustainability and risk management are key, especially in this industry because, firstly, we use natural ingredients for our products. If nature is not doing well enough and harvests are being compromised and destroyed by draughts and floods, the scarcity of basic resources we take for granted is an inevitable cost we will have to collectively bear as a society. Secondly, as a beverage brand, the transport emissions of our product are high, due to the heavy weight of the liquids. Implementing risk management strategies can help to reduce these emissions. Finally, the current way the beverage industry is organized is based on single-use of bottles and cans. This creates a large amount of waste that often isn’t adequately disposed of. In this article, I will comment on possible risk management solutions and opportunities that arise from these challenges.

Sustainability as a concept first surfaced in the report “Our Common Future” which was addressed to the World Commission on Environment and Development in 1987. Then, it referred to the link between forest cultivation and its preservation for future generations. A sustainable way to harvest a forest is to only take out as much wood each time as the ecosystem can handle. If too much timber is taken out, the ecosystem will degrade and erode. When the protective tree canopies disappear in too large amounts, the birds will leave the area, because they have no place to survive. The mosses will dry out because there is no shadow, which directly exposes them to the sun. The ecosystem will change and sometimes, if the cutting of trees is too severe, the landscape will degrade and be washed out by rain, which leaves it uninhabitable and unusable. We need to reverse this ecological snowball.

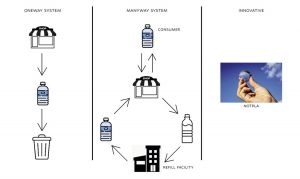

The beverage industry is wasteful because it utilizes a lot of water during beverage production, fossil fuels for transportation, and bottle production purposes, and because in India the industry is still very linear, many bottles and cans are disposed of straight away after use without proper care and end up in our oceans and landfills for generations. To eliminate resource waste, we are aiming to facilitate the many-way system. This means that we want to contribute to building, improving, and expanding a circular bottle reuse system.

Caption: The One-Way System and The Many-Way System

With the implementation of the many-ways system, bottles can be reused.

- Glass bottles: up to 50x (40x on average)

- PET plastic bottles: up to 25x (15x on average)

- Transport PET boxes: up to 100x

We aim to start by rolling out the many-way system from business to business before implementing it from business to consumer. B2B in this regard means between our company or the water refill plant and the hotels, restaurants, or caterers who Malaki already works with. The return of glass bottles with beverages that we sell to other businesses will be incentivized through a deposit scheme. Upon receiving a set of bottles in plastic boxes. A deposit payment for the bottles of hypothetically 10 rupees per bottle and 100 rupees per box will be billed to the client. Upon receiving the bottles back the 10 rupees for each bottle and 100 rupees for each box will be reverted to the client.

We will imply highly advanced technology that will be employed to check the bottles. The first machine called the sniffer, injects a nitrogen fog into the bottle. This allows for the detection and identification of any materials that were filled into the bottle before they are screened for wear and tear by the next machine. Implementing this system pan India will enable us to reduce our resource use dramatically, glass bottles can be reused up to 50 times, 40 times on average. And PET plastic bottles can be used up to 25 times, 15 times on average.

We do not want to shift to only using glass because the different packaging materials are useful for other purposes of our clients and customers. But we are excited to start implementing the many-way system. Our industry has a huge potential for positive change and we are looking forward to creating a big splash and with this a big wave towards more sustainable practices. We invite industry collaborators who share this dream of a sustainable and growing India to join us. We have an equal responsibility to build better, and together we can make a dent in our universe. Always remember: Don’t Stay Still, Sparkle!

Blog Author: Mohit Bhatia, Co-Founder, Malaki, Director, A1 Cuisines